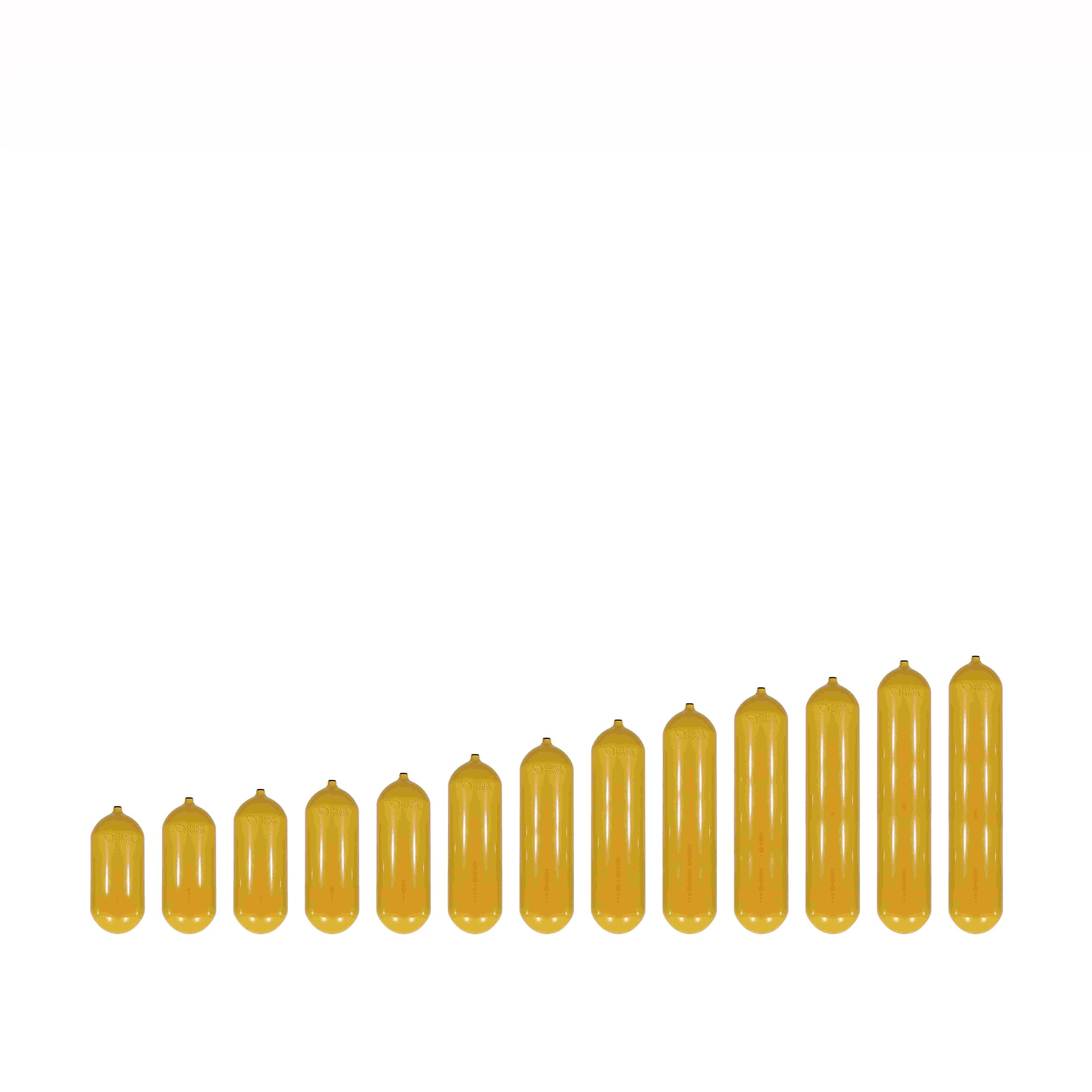

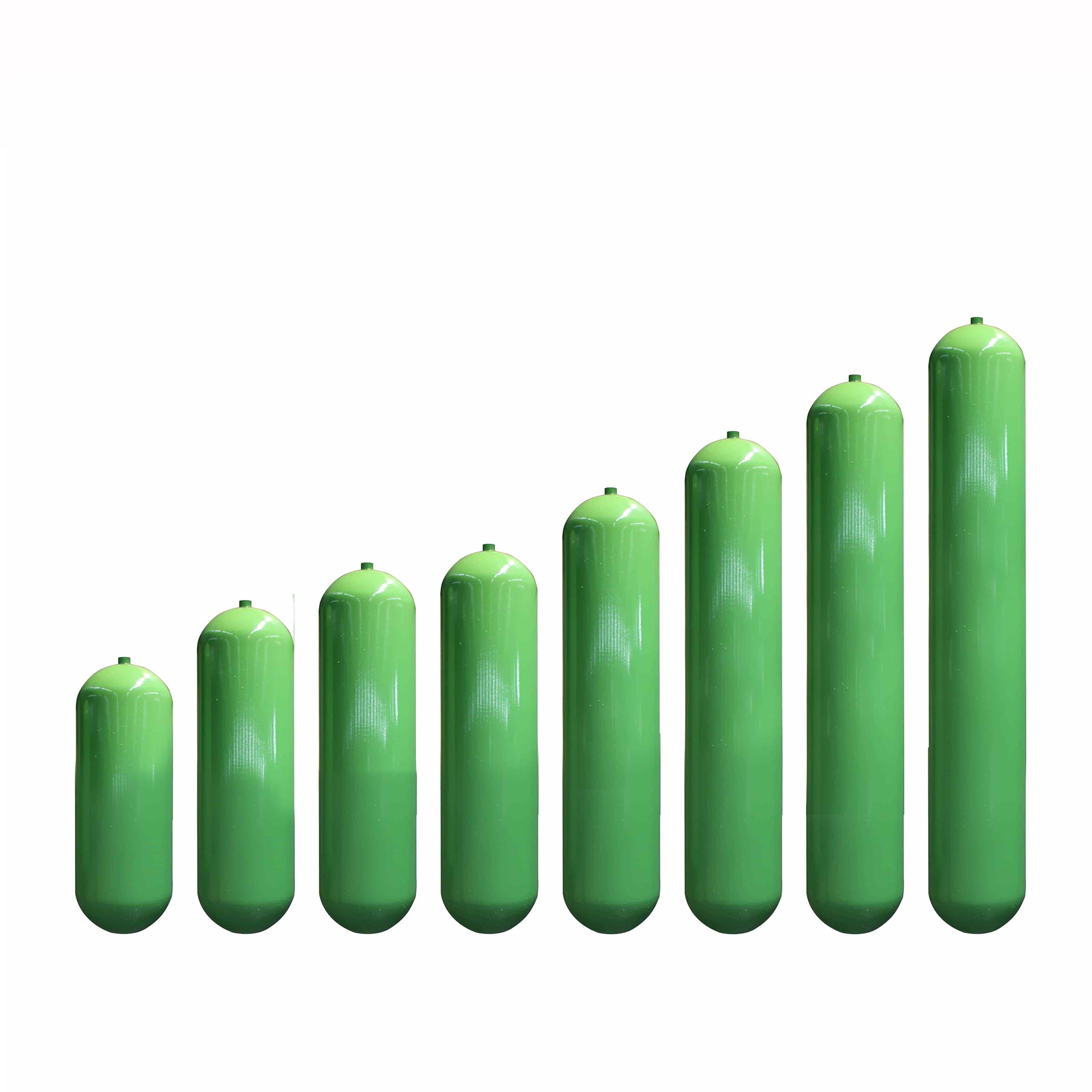

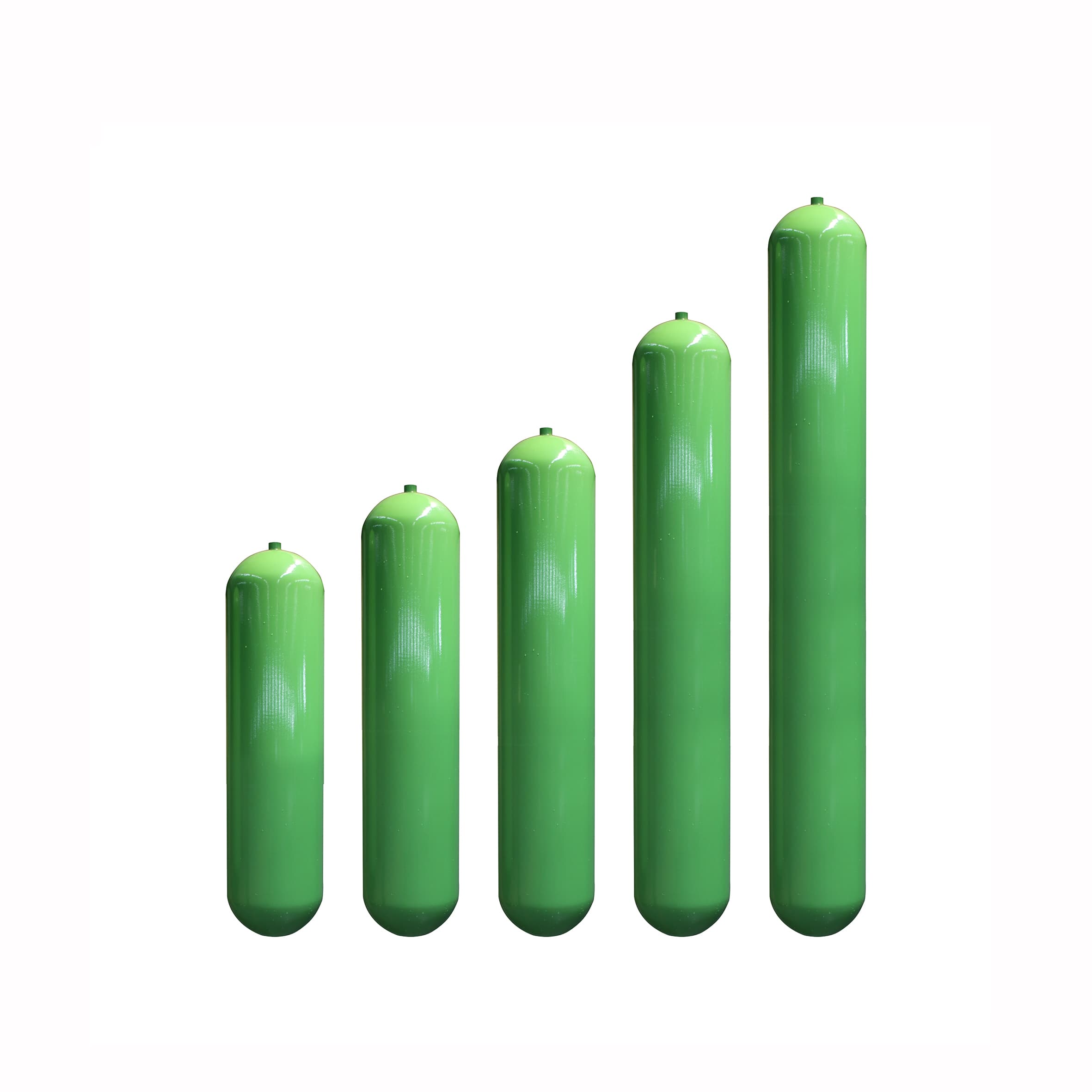

BOMBONA DE GAS GNC TIPO 2

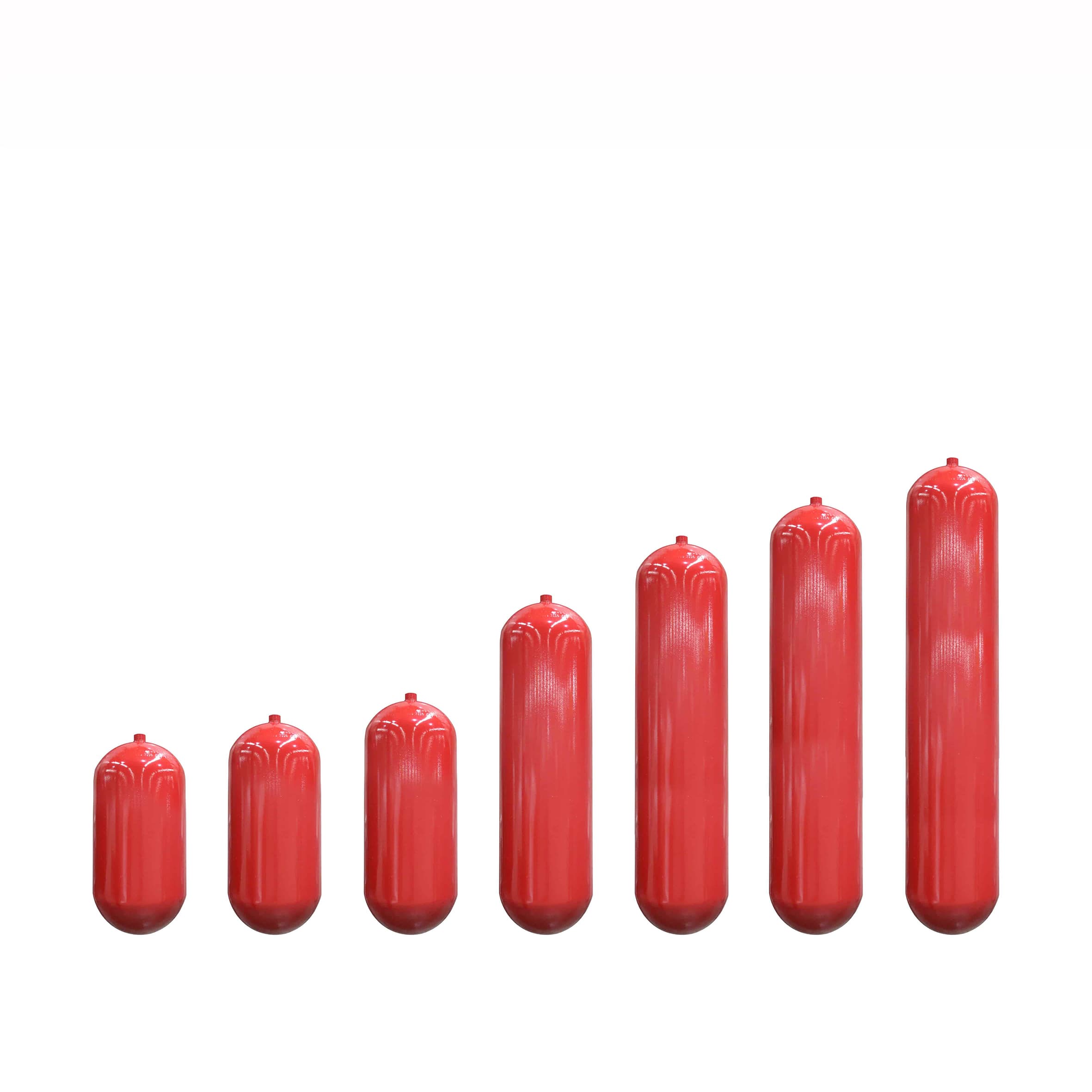

Cilindros de gas natural comprimido (GNC) Se utilizan para almacenar gas natural. Cilindros de GNC tipo II Están reforzados con materiales compuestos para mayor resistencia y seguridad. En comparación con otros tipos de cilindros, los cilindros de GNC Tipo II son más livianos que los cilindros de GNC Tipo I, lo que ayuda a reducir el peso total del vehículo. Pueden almacenar gasolina a presiones más altas y proporcionar una autonomía de conducción más larga.

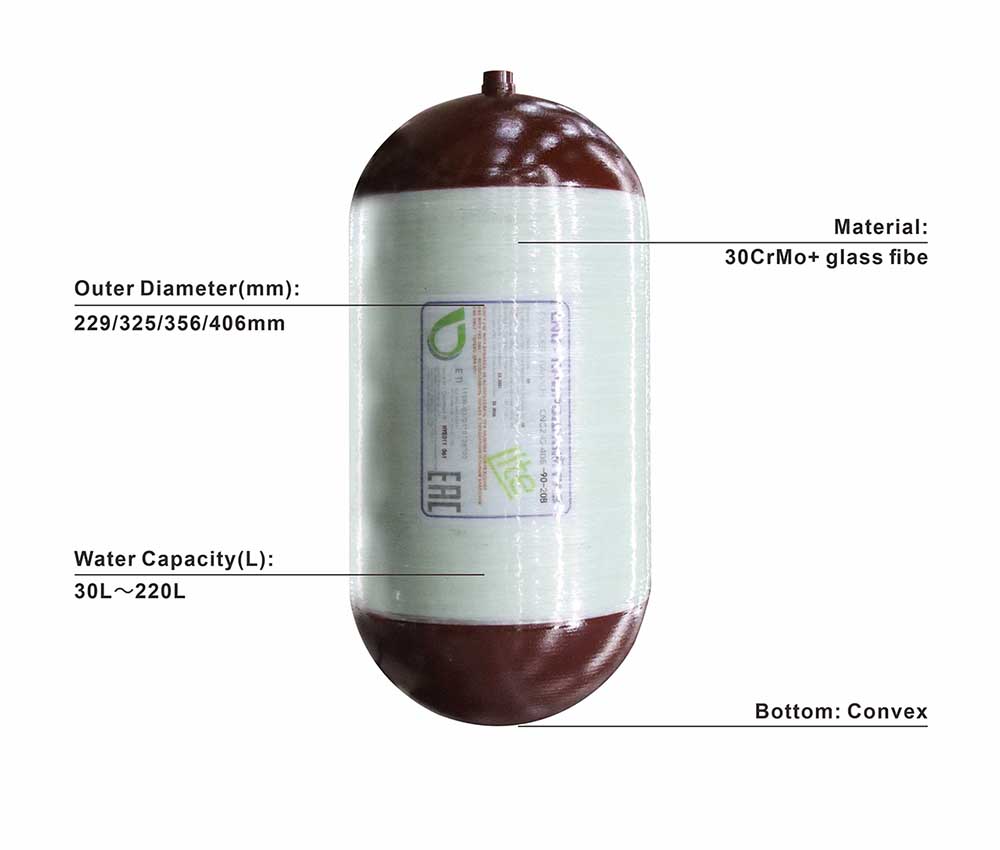

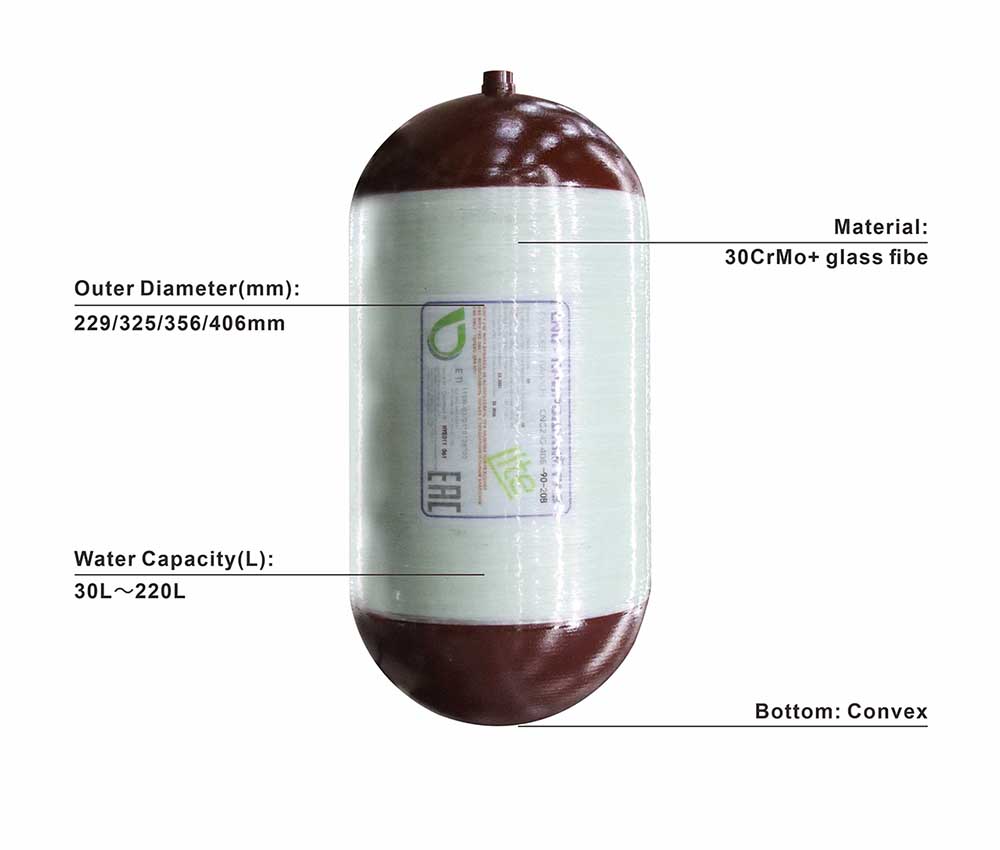

| Estándar de implementación | Trabajo normal Presión (barra) | Presión de prueba hidráulica (Bar) | Espesor de pared de diseño (mm) | Material | Forma inferior | Diámetro exterior (mm) | Capacidad de agua (l) | Longitud (mm) | Peso (kg) |

ECER 110 ISO11439-2013 | 200 | 300 | 4.6 | 30CrMo | Convexo | 325 | 60 | 910 | 46,5 |

| 65 | 965 | 50.0 |

| 100 | 1430 | 74,5 |

| 120 | 1690 | 88,5 |

Rango de aplicación:

Los cilindros de GNC II se utilizan habitualmente para almacenar gas natural comprimido, que puede utilizarse como combustible para motores de vehículos, utilizados principalmente en taxis urbanos, autobuses y turismos particulares.

¿Por qué elegirnos?

- Fuerte capacidad de producción: Con una fábrica autoconstruida que cubre más de 56.000 metros cuadrados y emplea a más de 240 personas, la empresa tiene capacidad para producir 300.000

- Ventas directas desde la fábrica de origen: al eliminar las empresas de comercio exterior, los compradores pueden acceder directamente al fabricante para realizar adquisiciones en un solo lugar.

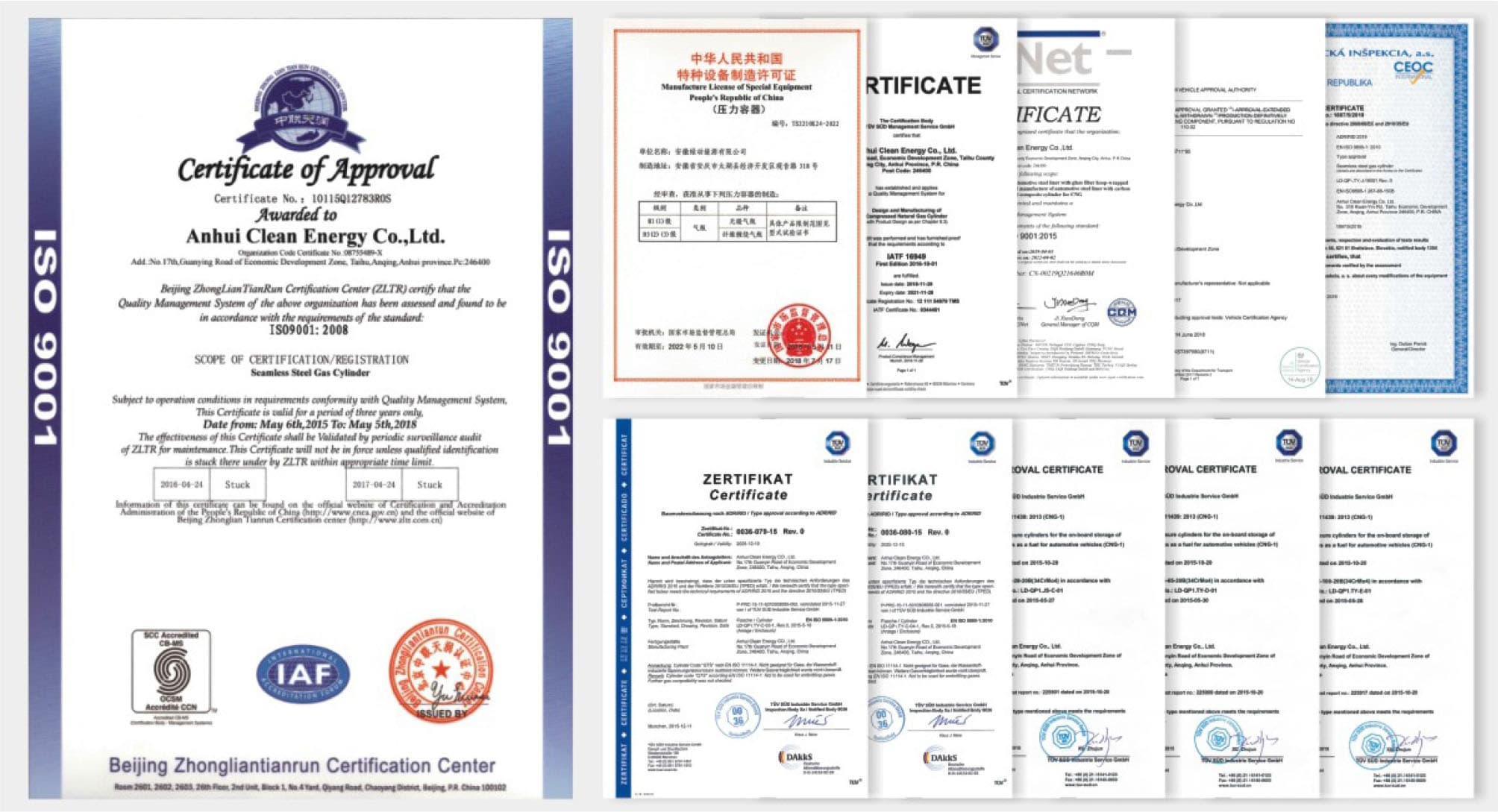

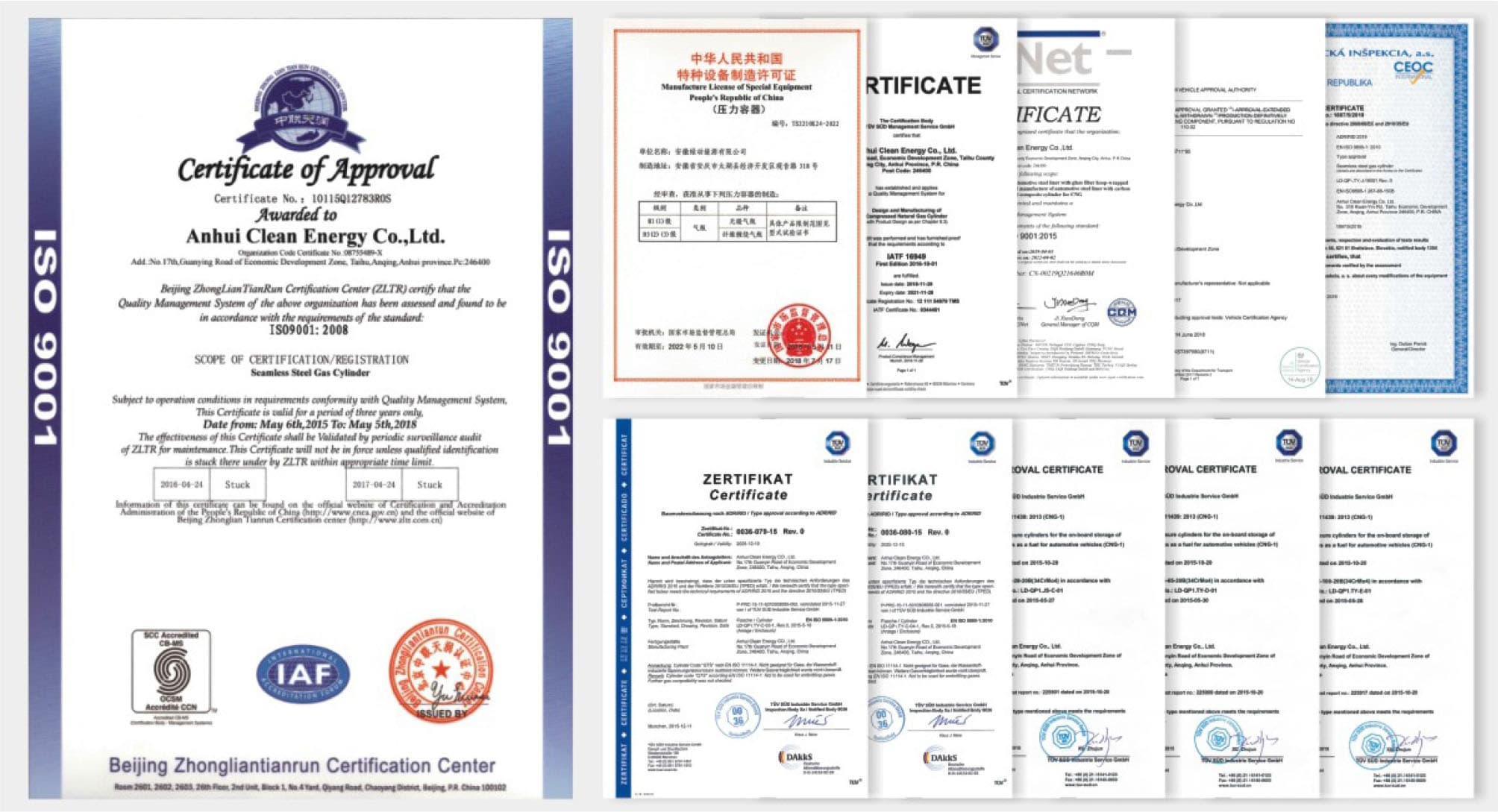

- 10 años de experiencia en la industria: la fábrica tiene IATF 16949 y Norma ISO 9001 certificados del sistema de gestión de calidad,

- Capacidad de personalización: Nuestros productos se pueden personalizar según sus preferencias, incluido el color, el tamaño, el hilo y el logotipo.

- En la actualidad, la empresa cuenta con 6 líneas de producción de hilado de cilindros de gas, 3 líneas de tratamiento térmico y templado, 2 líneas de producción automáticas para adición, pulverización y bobinado de máquinas, y 1 línea de producción de cilindros de gas compuesto de GLP.

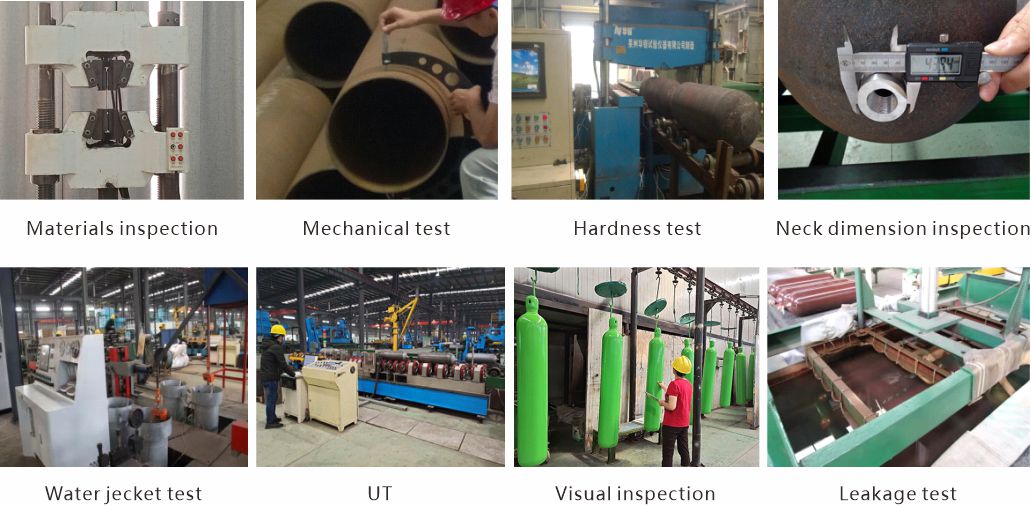

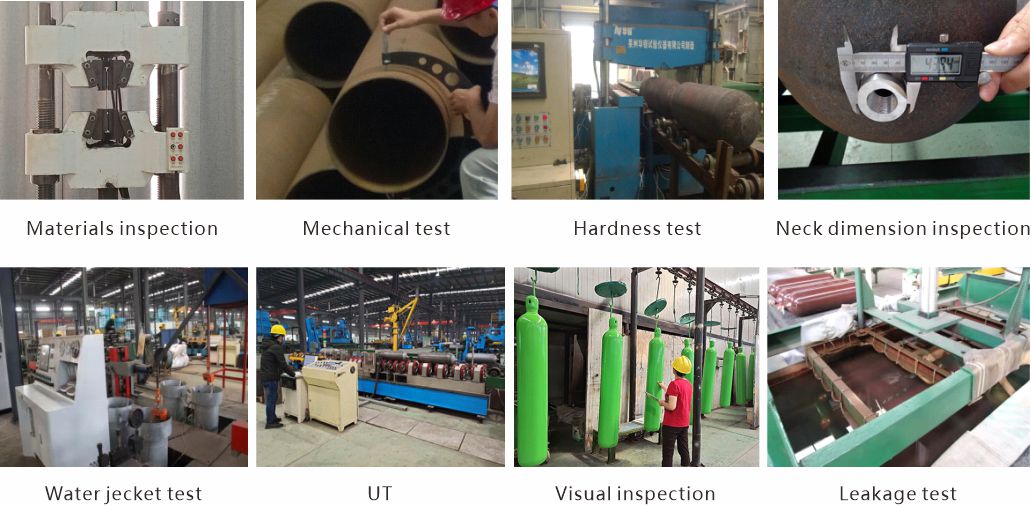

Pantalla de inspección de productos de cilindros de GNC

Después de muchas pruebas de cilindros, la fábrica garantiza que el producto sea seguro y confiable, para que pueda comprarlo y usarlo con confianza. Cada procedimiento de inspección ha sido diseñado científica y rigurosamente, y no hay lugar para negligencias. Desde la selección de materiales hasta el proceso de producción, los cilindros de GNC se esfuerzan por combinar una calidad excepcional con una seguridad impecable. Cada enlace muestra una artesanía exquisita y garantía de calidad.

Control de calidad

Nuestros productos cuentan con ISO 11439, ISO11119, ISO9089, ONU ISO9809, ECE R110, EN11245 y otros certificados internacionales, así como los propios ISO9001 e IATF 16949 de la empresa y otros certificados de sistemas de calidad internacionales.

Desde su creación hace más de diez años, la empresa cuenta con una fábrica de construcción propia que cubre una superficie de 56.000 metros cuadrados. Actualmente contamos con una plantilla de 240 empleados, incluidos 50 miembros del personal técnico y de gestión de alto nivel. Además, poseemos la capacidad de producción para fabricar 300.000 distintos tipos de cilindros de gas al año, así como 9.000 conjuntos de estructuras de GNC y sistemas de suministro de gas.

Idioma

:

Idioma

: English

English français

français español

español

Red IPv6 compatible

Red IPv6 compatible