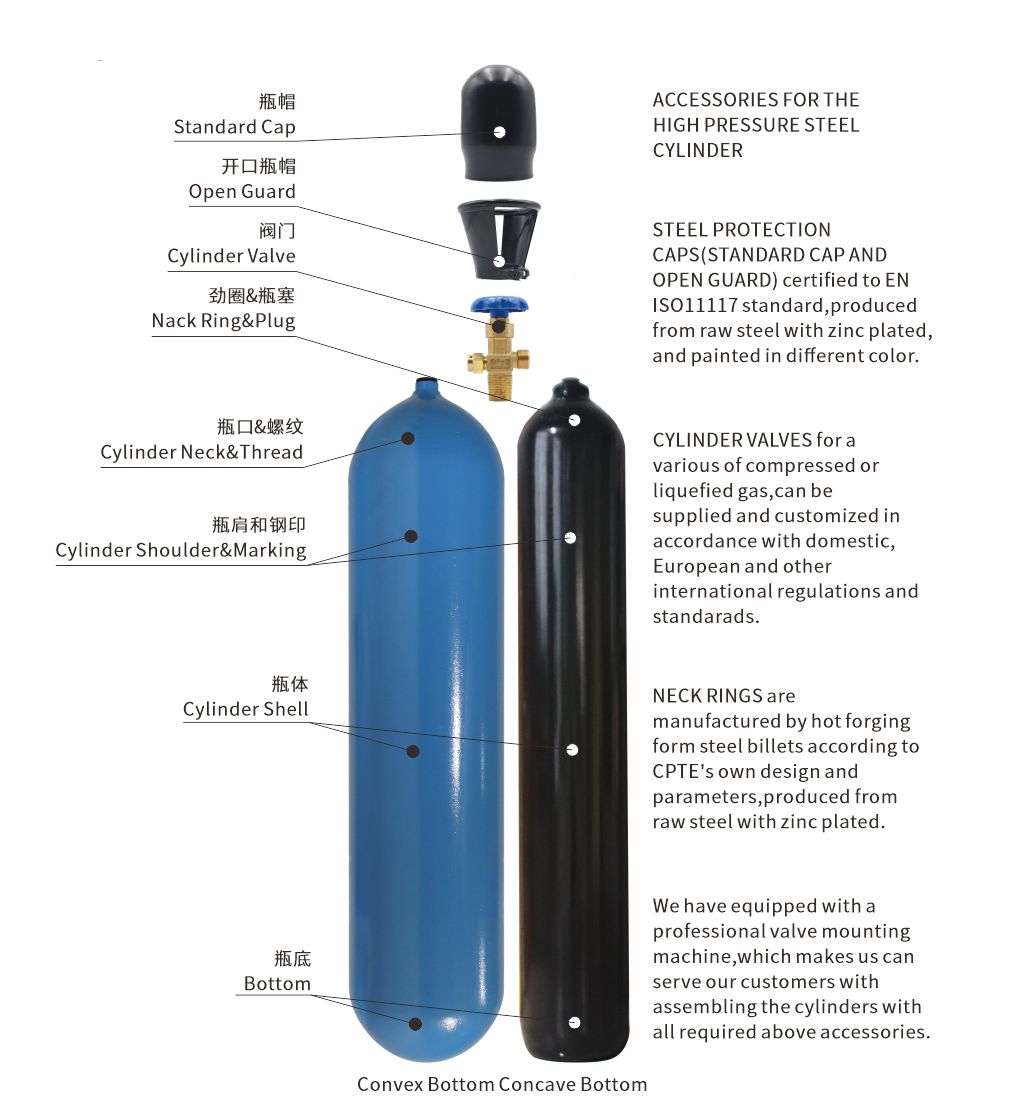

Cilindro de gas de acero sin costura

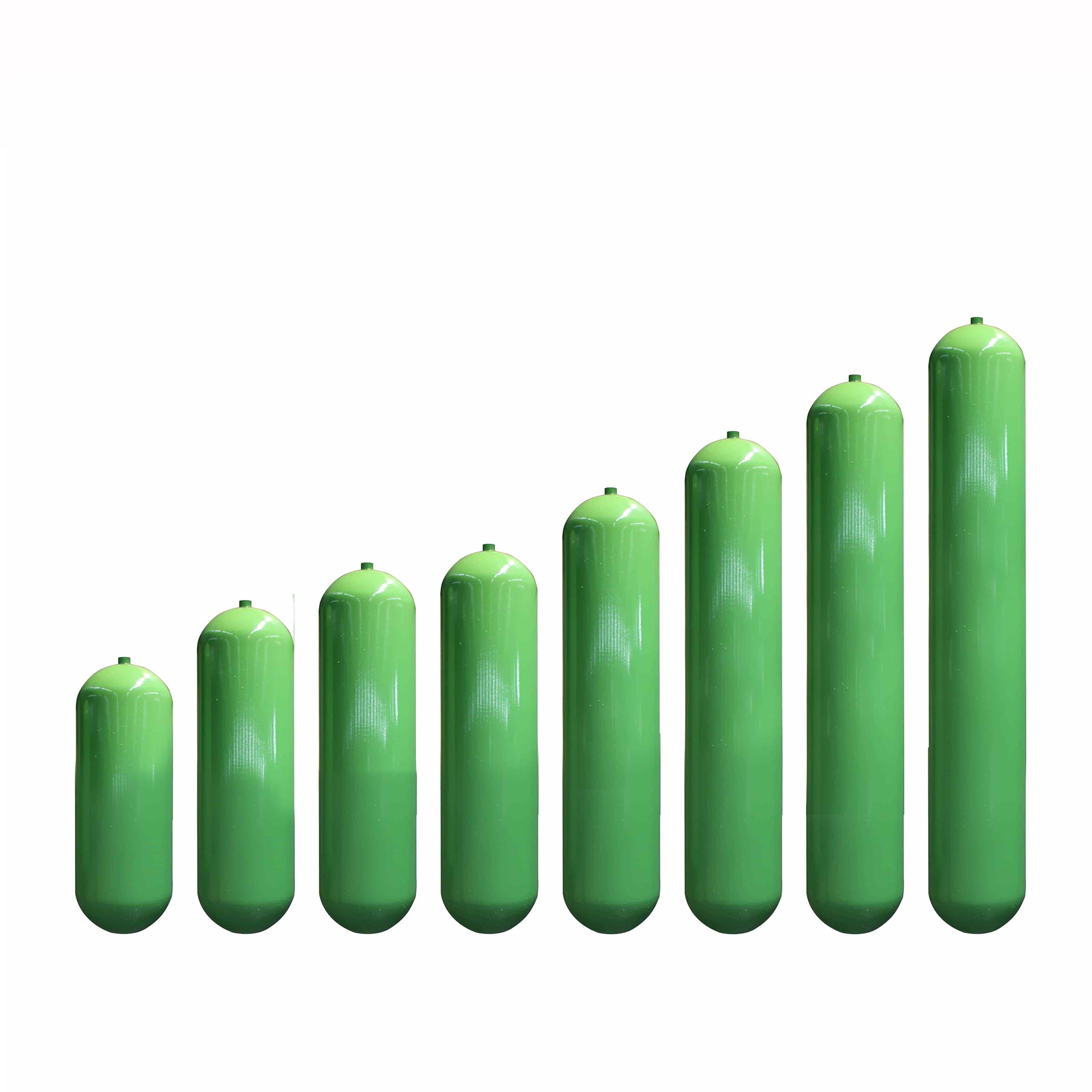

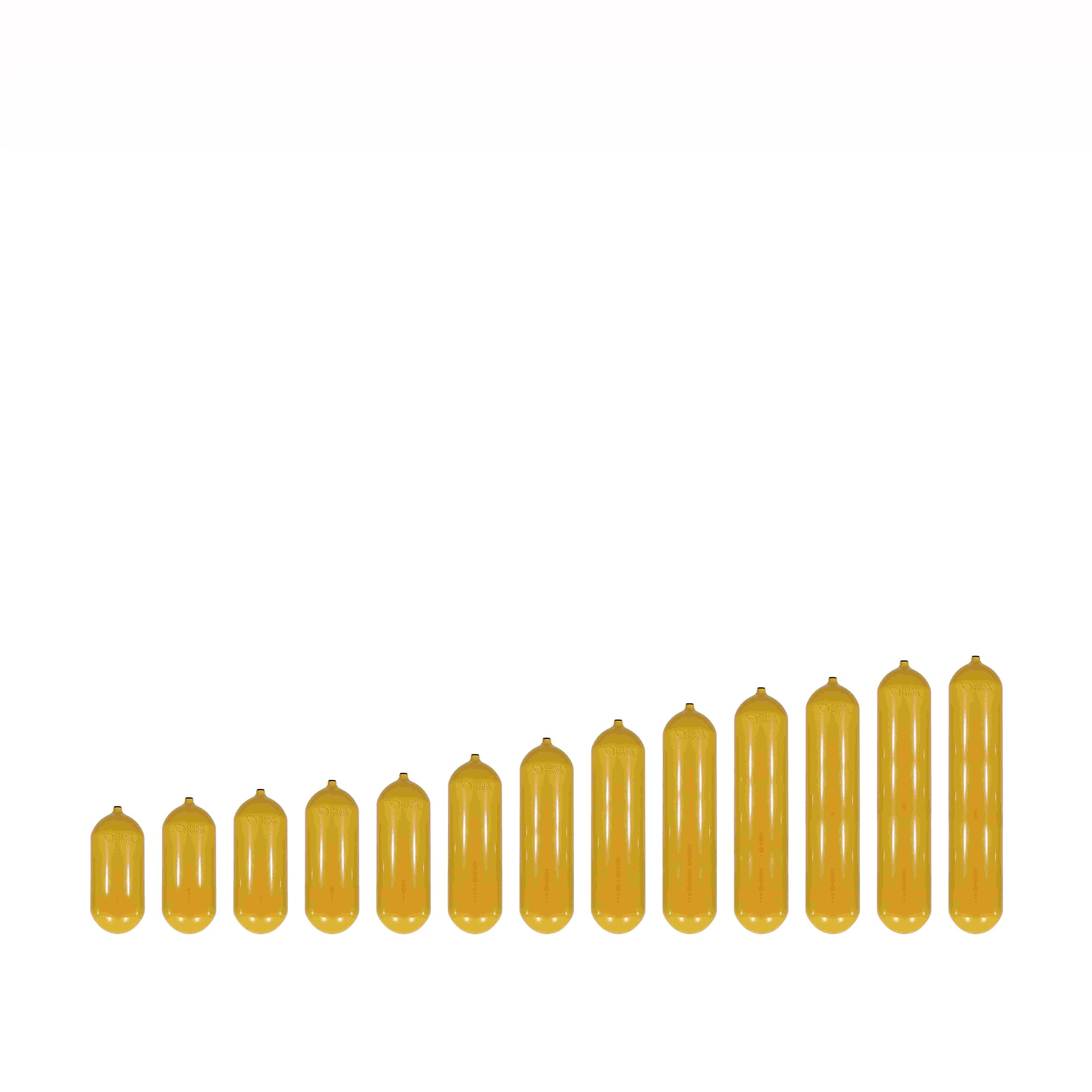

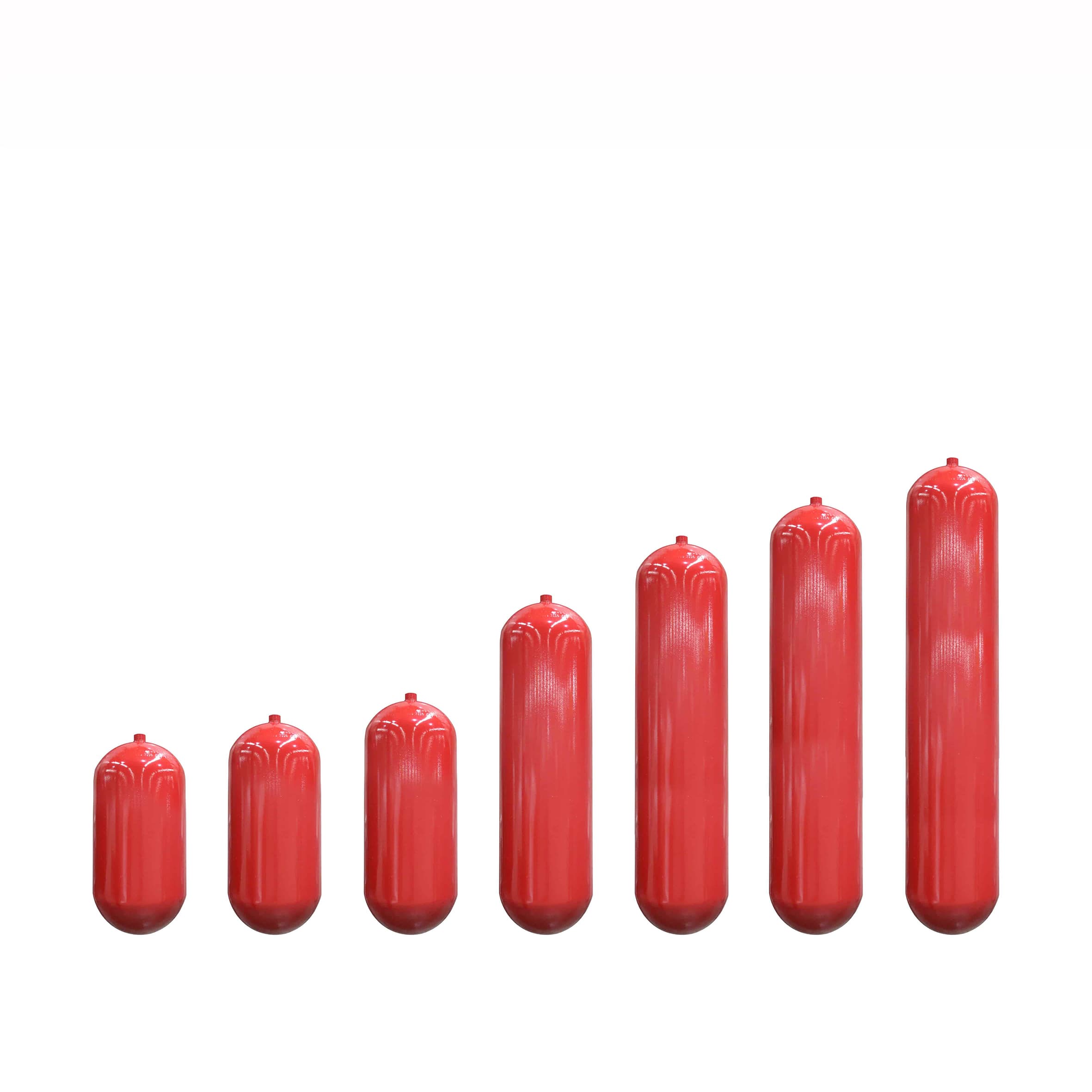

Nuestro cilindro de gas industrial Los diseños priorizan la durabilidad y la seguridad, utilizando procesos de fabricación avanzados y un riguroso control de calidad para garantizar que cada cilindro pueda soportar entornos de alta presión y un uso a largo plazo. Ofrecemos una variedad de tamaños para cilindros de gas industriales, que van desde 60 L hasta 105 L, para satisfacer las necesidades de las industrias.

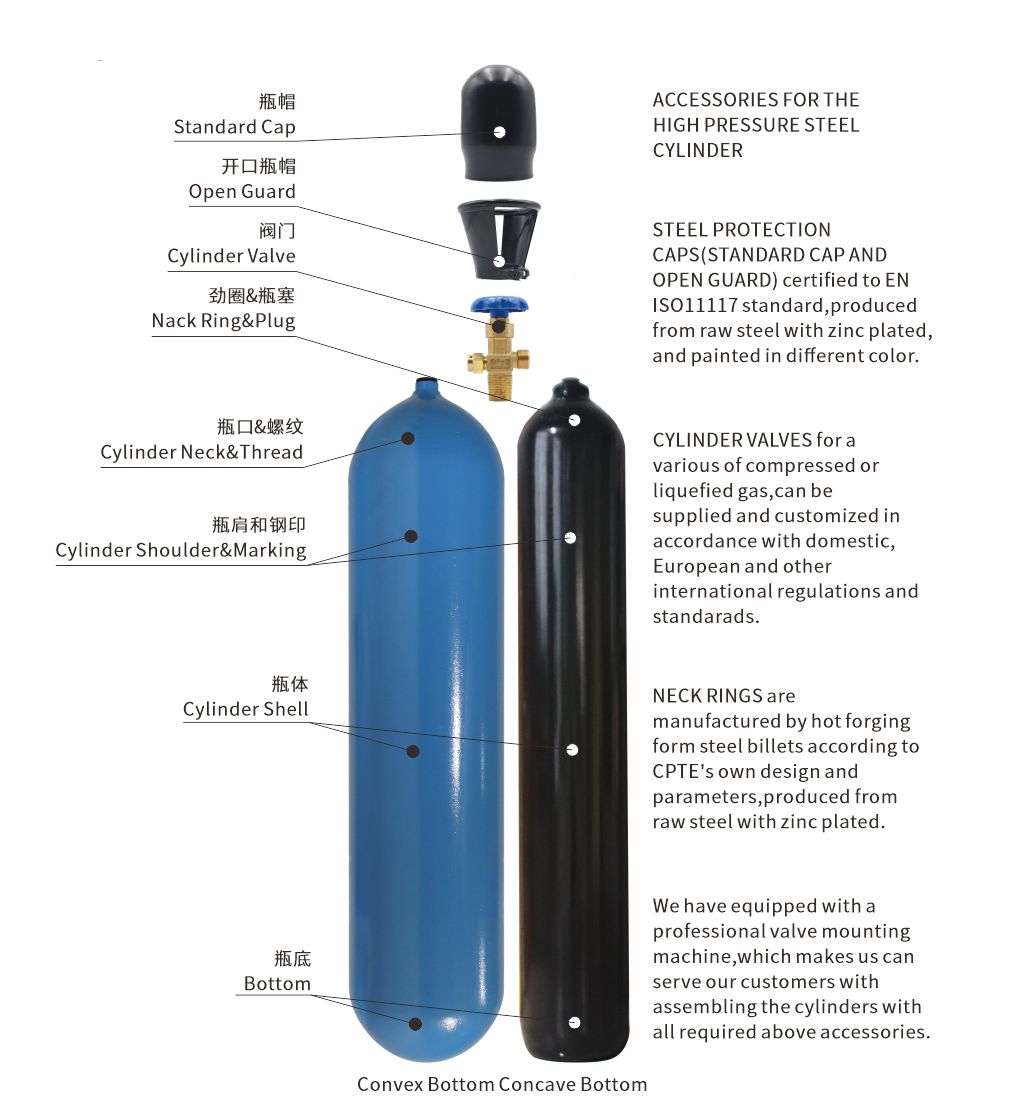

| Estándar de implementación | Modelo de cilindro

y estándar | Presión de trabajo normal | Presión de prueba hidráulica | Espesor de pared de diseño

(mm) | Material | Forma inferior | Diámetro exterior

(mm) | Capacidad de agua

(L) | Longitud

(mm) | Peso

(kg) |

| DOT-3AA | 279-V-2495 psig | 172 barras

(2495 psig) | 287 barras

(4163 psig) | 7.1 | 30CrMo

(4130X) | Cóncavo | 279 | 70 | 1448 | 88.2 |

Rango de aplicación

Industria del petróleo y el gas: los cilindros de gas se utilizan para almacenar y transportar gases licuados, gas natural y otros gases industriales como nitrógeno, oxígeno, argón, etc.

Industria química: los cilindros de gas se utilizan para almacenar y transportar diversos gases químicos, incluidos amoníaco, cloro, etileno, etc. Estos gases tienen amplias aplicaciones en la producción química y los cilindros de gas proporcionan una solución de almacenamiento segura y estable.

Industria metalúrgica: los cilindros de gas industriales se utilizan para almacenar gases utilizados en la fundición de metales, como oxígeno, nitrógeno, argón, etc. Estos gases se utilizan en soldadura, corte y otros procesos de procesamiento de metales.

Industria médica: los cilindros de oxígeno se utilizan ampliamente en hospitales y otras instituciones médicas para brindar asistencia respiratoria a los pacientes. Además, los cilindros de gas también se utilizan para el suministro de gas en algunos equipos.

¿Por qué elegirnos?

- Fuerte capacidad de producción: Con una fábrica autoconstruida que cubre más de 56.000 metros cuadrados y emplea a más de 240 personas, la empresa tiene capacidad para producir 300.000

- Ventas directas desde la fábrica de origen: al eliminar las empresas de comercio exterior, los compradores pueden acceder directamente al fabricante para realizar adquisiciones en un solo lugar.

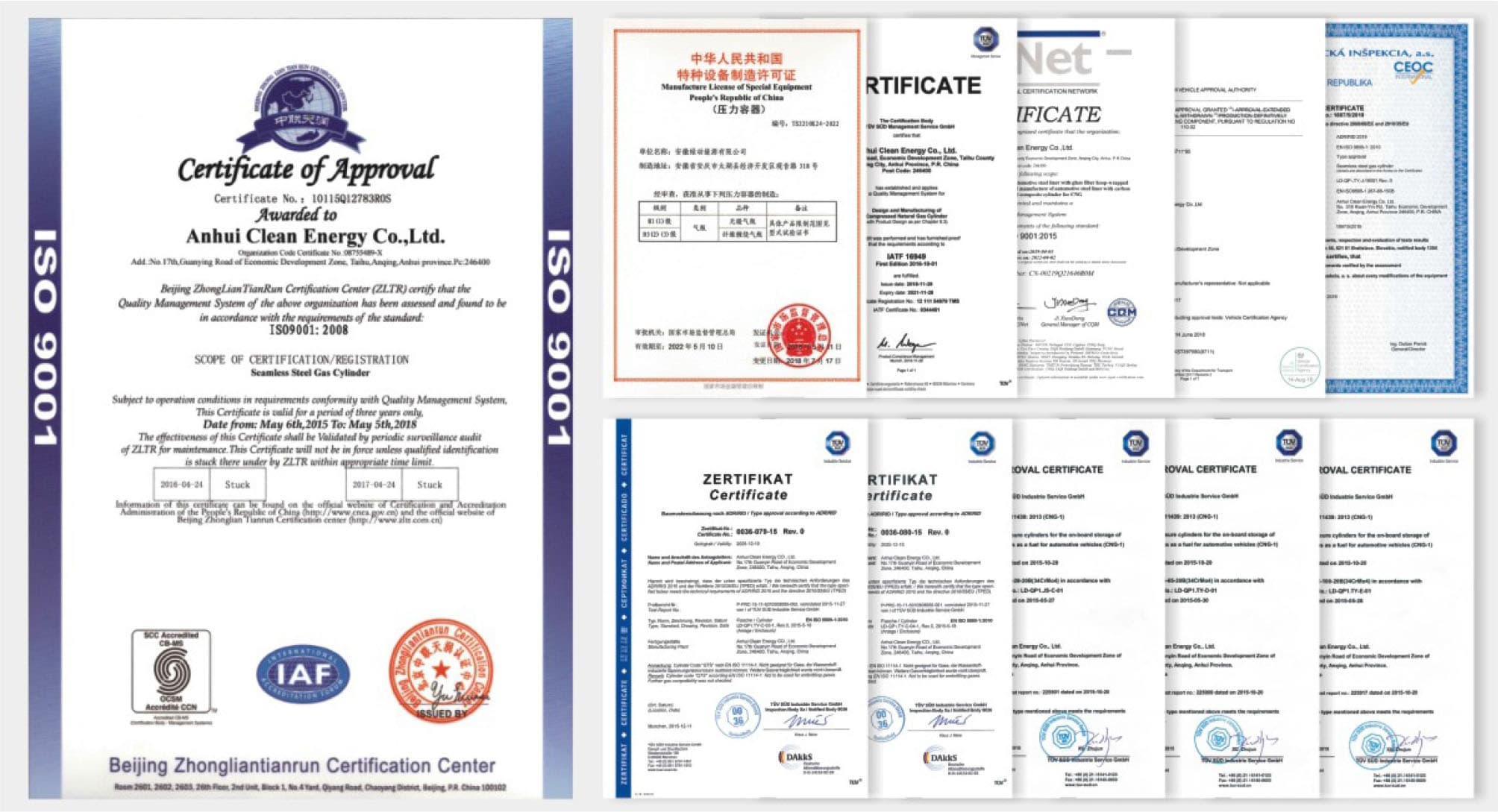

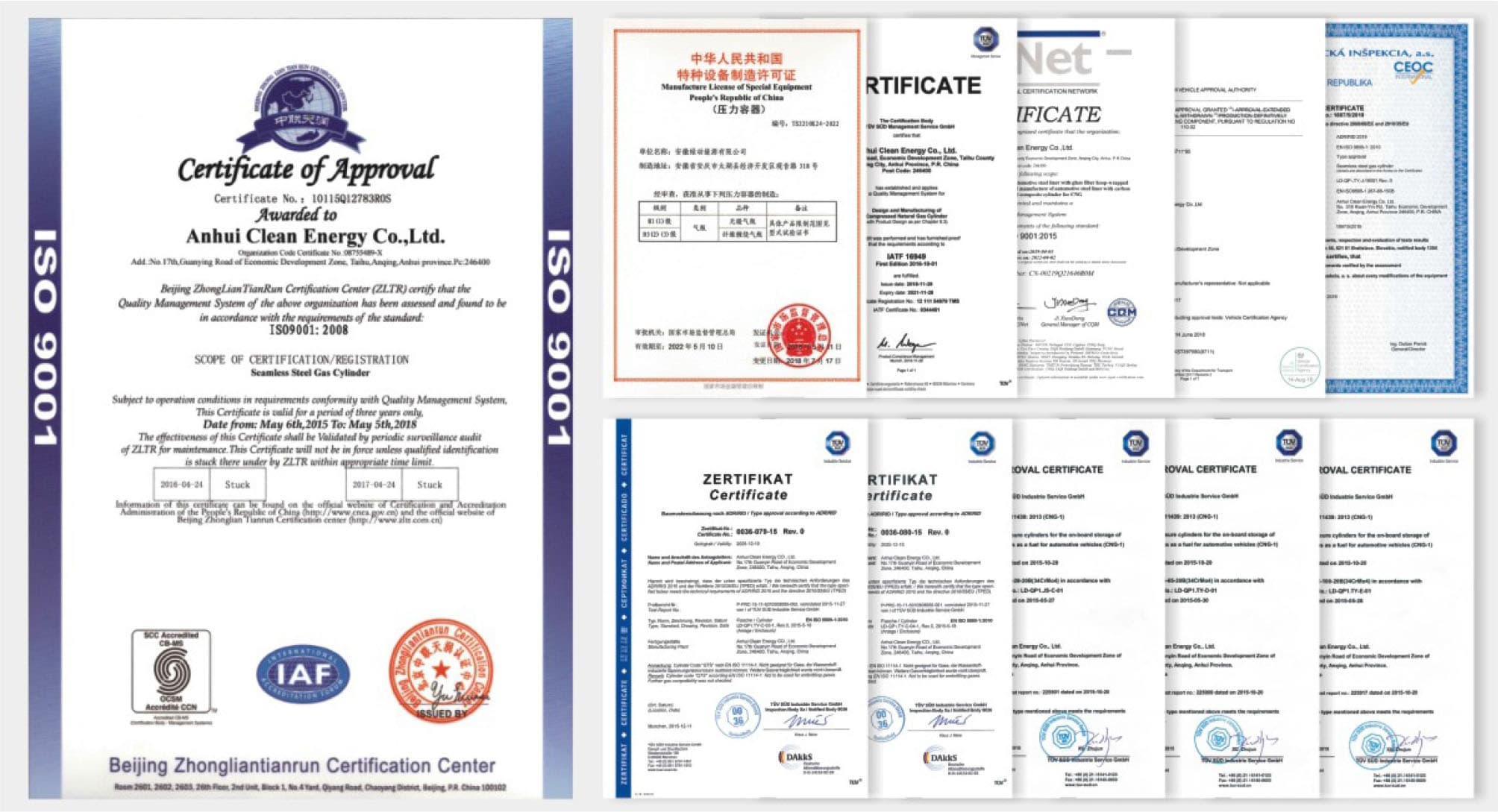

- 10 años de experiencia en la industria: la fábrica cuenta con certificados de sistemas de gestión de calidad IATF 16949 e ISO 9001,

- Capacidad de personalización: Nuestros productos se pueden personalizar según sus preferencias, incluido el color, el tamaño, el hilo y el logotipo.

- En la actualidad, la empresa cuenta con 6 líneas de producción de hilado de cilindros de gas, 3 líneas de tratamiento térmico y templado, 2 líneas de producción automáticas para adición, pulverización y bobinado de máquinas, y 1 línea de producción de cilindros de gas compuesto de GLP.

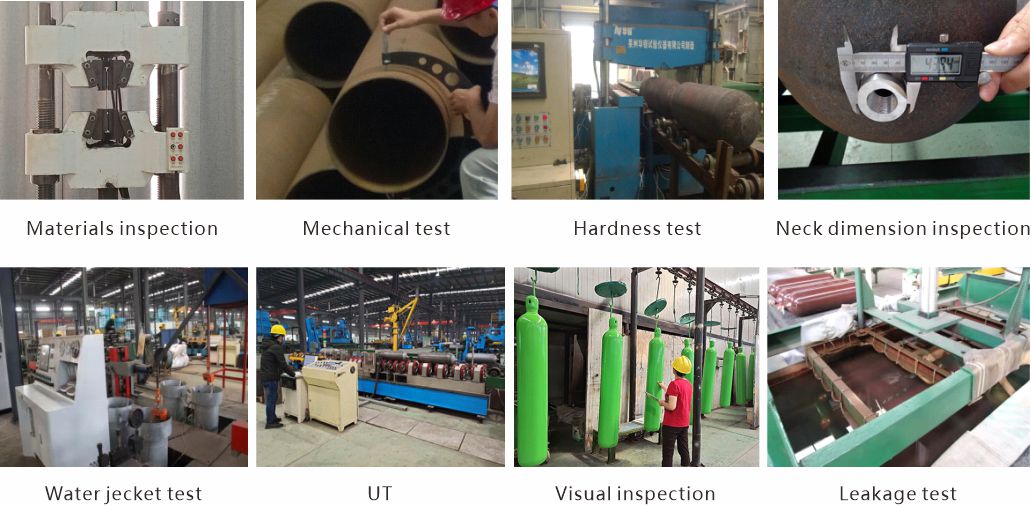

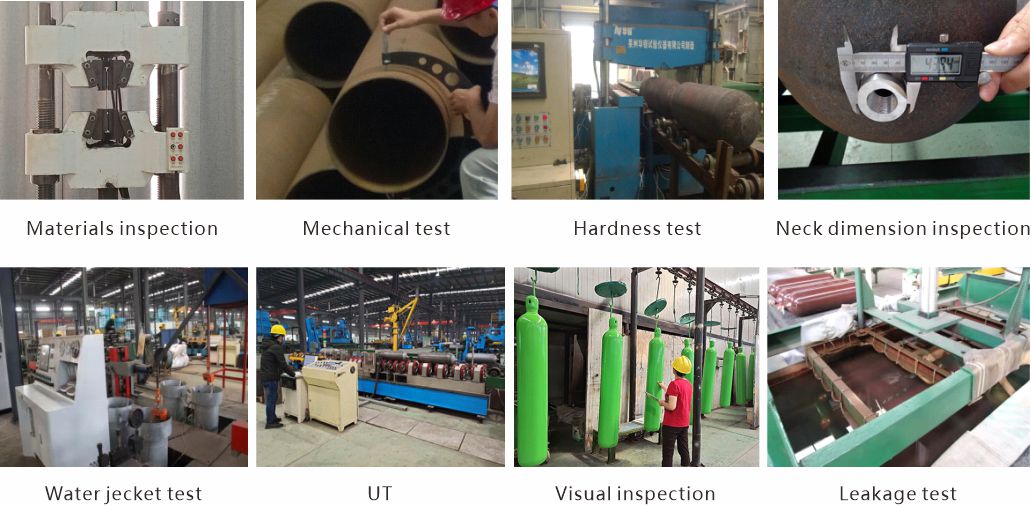

Pantalla de inspección de productos de cilindros

La fábrica se somete a múltiples inspecciones de cilindros para garantizar la seguridad y confiabilidad del producto, para que pueda comprarlo con confianza y usarlo con seguridad. Cada procedimiento de inspección es científico y riguroso, sin dejar lugar a negligencias. Desde la selección de materiales hasta los procesos de producción, los cilindros se esfuerzan por combinar una excelente calidad con una seguridad impecable. Cada aspecto destaca la exquisita artesanía y la garantía de calidad.

Control de calidad

Nuestro vaciar cilindros de gas Contamos con certificaciones internacionales como ISO 11439, ISO11119, ISO9089, UN ISO9809, ECE R110, EN11245, así como certificaciones propias de sistemas de calidad internacionales como ISO9001 e IATF 16949. Sabemos que deseas seguir mejorando la calidad de tus productos. Por otro lado, prestamos atención al detalle y prestamos atención a la calidad. Porque creemos que cada pequeño paso repercute en el valor y la calidad del producto final.

Desde su creación hace más de diez años, la empresa cuenta con una fábrica de construcción propia que cubre una superficie de 56.000 metros cuadrados. Actualmente contamos con una plantilla de 240 empleados, incluidos 50 miembros del personal técnico y de gestión de alto nivel. Además, poseemos la capacidad de producción para fabricar 300.000 distintos tipos de cilindros de gas al año, así como 9.000 conjuntos de estructuras de GNC y sistemas de suministro de gas.

Idioma

:

Idioma

: English

English français

français español

español

Red IPv6 compatible

Red IPv6 compatible